Why Make Flowmeter Split?

In the intricate layout of industrial process control and monitoring, flow meters can play a paramount role, performing accurate measurement of fluid flow to guarantee efficient, high-quality, and safe processes. Among a variety design of flowmeters, remote-mount split type flow meters are particularly noteworthy: sensor and converter are separated into two distinct components connecting by cable.

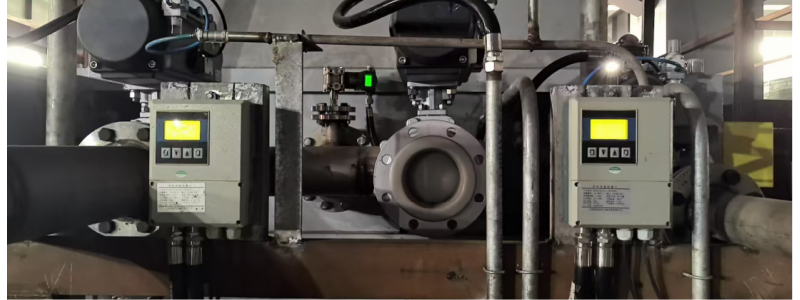

As the term suggests, a split-type flowmeter consists of two separate, discrete units:

The two units are connected by specialized cables carries both power to sensor and signal back to converter.

Conventional integral flowmeter houses sensor and converter together into a single enclosure attached to the pipe. It presents a unified, all-in-one solution while split flowmeter is a modular system. The crucial distinction gives split flowmeter multiple advantages in various aspects:

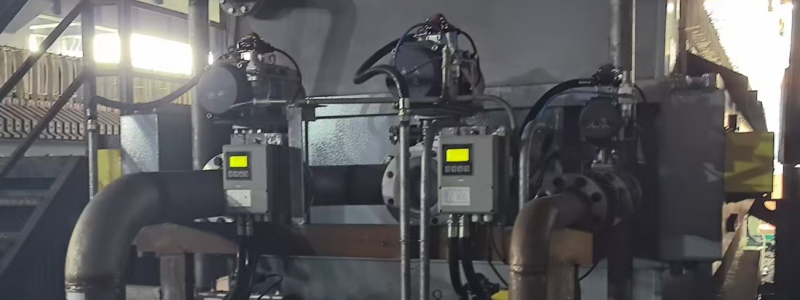

Mounting Flexibility and Accessibility: In many industrial settings, the ideal point for flow measurement may in a location extremely challenging for personnel to access — underground in a pit, several meters high on a pipe rack, in a congested area amidst other equipment, with extreme ambient temperatures,etc. A split design allows the sensitive electronics of converter to be mounted in a safe, accessible, and environmentally controlled location. Operators can easily read the display, configure settings, and perform diagnostics without needing safety harnesses, ladders, or exposure to harsh conditions.

Improved Sustainability in Extreme Conditions: Flow sensor is built to endure the process fluid’s conditions, but converter’s electronics are sensitive to ambient temperature, humidity, vibration, and electromagnetic interference (EMI). By physically separating the two components, converter can be placed in a benign environment ensuring signal integrity, measurement stability, and a longer lifespan. This is rather effective for applications where the process is exposed to weather, steam, corrosive atmospheres, or high levels of vibration.

Ease of Maintenance and Reduced Downtime: If converter of split flowmeter fails or requires recalibration, it can be replaced or serviced without disturbing the sensor or shutting down the process. The modularity drastically reduces maintenance time and cost. Technicians can simply disconnect the old converter and plug in a new or pre-configured spare unit. In contrast, replacing an entire integral flowmeter often requires a full process shutdown, pipe draining, and re-installation that could be far more disruptive and costly.

Standardization and Cost-effectiveness: In large facilities with numerous flow points, standardized converter model could be paired with sensor of various types and sizes. The interoperability simplifies spare parts inventory management and ease training requirements for maintenance staff. Furthermore, if technological advancements are made in converter design, flow sensors can often be retained while only converters are upgraded.

Split design provides unparalleled flexibility, resilience, and ease of maintenance for flow monitoring solutions. By separating rugged sensor from intelligent converter, engineers can achieve reliable and accurate flow measurement in the most demanding and inaccessible applications, ensuring process integrity while optimizing long-term operational costs. Shanghai Wangyuan is a high-tech manufacturer and supplier with over 20 years experience specializing in measurement instrumentation. If you have any demands or doubts regarding split-type flowmeters, please feel free to get in further touch with us for solutions.