Why do some DP Transmitters Output Square Root Signal?

In practice of differential pressure monitoring, we can notices that sometimes output of differential pressure transmitter is required to be processed into square root 4~20mA signal. Such applications often occur in industrial flow measurement system utilizing differential pressure principle that is one of the popular approaches for flow rate monitoring. After DP flow measurement is briefly reviewed can we understand the role of differential pressure transmitter in assisting flowmeter operation.

Flow meters serve a vital role in monitoring fluid rate among complicated industrial pipeline network by providing flow reading on timely and precise bases that contributes to effective material management and operational safety. Differential pressure approach is one of the major flow measurement technologies that includes types of flowmeters. They’re different in structure but share similar operating objectives to create pressure gap for flow computation that based on key principle of Bernoulli’s Equation: The total energy consisting of kinetic and potential energy in fluid flow remains constant irrespective of conditions. Therefore primary element of those DP flowmeters is essentially a throttling device(orifice plate, venturi tube, pitot tube, v-cone, etc.) to create flow acceleration in local section, leading to drop in hydrostatic pressure of fluid.

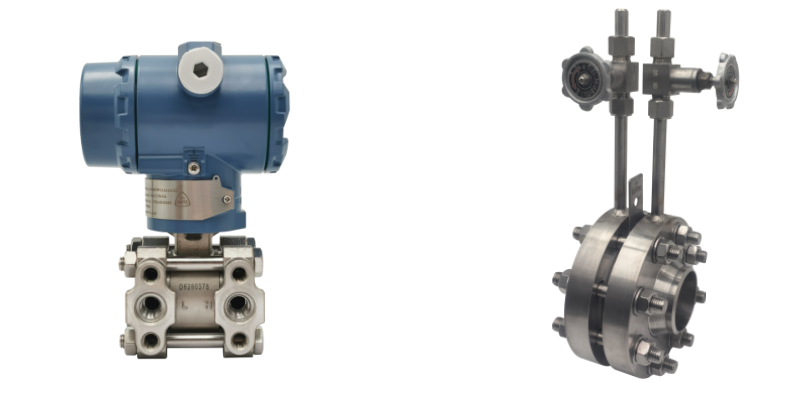

This is where differential pressure transmitter comes into play. The primary elements are merely mechanical devices, they physically generates pressure difference in the process but none of them is able to directly measure the value and output signal. So they need an assistant to detect the differential pressure between upstream and downstream and ultimately convert it into output signal of flow measurement value —— sounds like a well-suited task for differential pressure transmitter.

After DP measurement is established, the question would be how can differential pressure and volumetric flow rate be related? Base on Bernoulli’s Equation and Continuity Equation, a nonlinear relationship exists between the generated differential pressure (ΔP) and the actual fluid flow rate (Q):

Q=K√ΔP

Where K represents a meter-specific coefficient decided by factors the type of primary element and several other factors (fluid density, pipe size and so on). Transmitter’s raw 4~20mA signal is not linear to flow rate and unable to properly represent its trend. The issue can be resolved by integration of square root extraction (SRE) that square roots the native ΔP making the signal proportional to volumetric flow rate in the end.

If the transmitter is not able to execute SRE internally, computation has to be handled by external flow computer or control system which could compound complexity and potential error points in signal routing. Therefore modern DP transmitters usually have built-in signal SRE function on analog circuit and can output square rooted 4~20mA. What’s more, DP transmitters can implement low flow cut-off to mitigate sensor drift which could be disproportionately magnified at low flow rate. This software function forces the output to 4 mA (0% flow) when the computed flow falls below a defined threshold to avoid erratic signal and false flow accumulation.

Differential pressure flow measurement systems are one of the most proven and popular flow control technologies. While they offer outstanding advantages, there’re also limitations due to the structure and principle:

+ Standardized design, well-established technology

+ Robust and durable structure, no moving parts

+ Improved accuracy and stability

- Permanent pressure loss

- Narrow turndown ratio

- Sensitive to changes in fluid density and other factors

Selecting appropriate flowmeter is vital for efficiency and accuracy of fluid flow measurement. By comprehensively considering operating factors can users make informed decisions that align with specific demands. Shanghai Wangyuan has been engaged in manufacturing and service of measurement and control instrumentation for over 20 years including all kinds of flowmeters, differential pressure transmitters and other fittings for flow measurement. Should you have any further question or requirement, please do not hesitate to contact us.